TechRev 4.0: Smart Factory

Real time data acquisition

Continuous process monitoring by digital twin

Performance measuring & appraisal

Live Dashboard & advanced visual analytics

Better informed decision making

PRESENT CHALLENGES IN RMG MANUFACTURING

In the RMG industry, a concerning trend of rising material costs and worker wages amid falling global garment prices is challenging for business owners. While these external factors are beyond control, internal manufacturing challenges offer room for improvement. Enhancing production processes, enforcing quality control, optimizing inventory management, fostering a skilled workforce, and embracing sustainable practices are within our control. Addressing these challenges can drive efficiency, reduce costs, and ensure sustained profitability in the face of external constraints.

Bangladesh Average

Efficiency

Wastage

Defect

Global Standards

Efficiency

Wastage

Defect

The Hidden Truth

Lack of Real-Time Data

Traditional manufacturing processes in the readymade garments industry often rely on manual tracking and reporting systems. This results in limited visibility into various stages of production, making it difficult for manufacturers to monitor progress, identify bottlenecks, and respond swiftly to issues.

Limited Visibility

Without real-time data, it becomes challenging to accurately forecast demand and adjust production schedules accordingly. This can lead to overproduction, excess inventory, or missed sales opportunities.

The Solution

SYSTEM COMPONENTS

SmartTrack Data Terminal

Our data terminals are suitable to function in a harsh industrial environment with no maintenance for years to achieve your objective with seamless performance. They come as a plug-and-play type and are ready to collect data flawlessly.

SmartTag and SmartCard

All the tags and cards are designed to work seamlessly in an industrial environment. These are reusable for years without the need for maintenance.

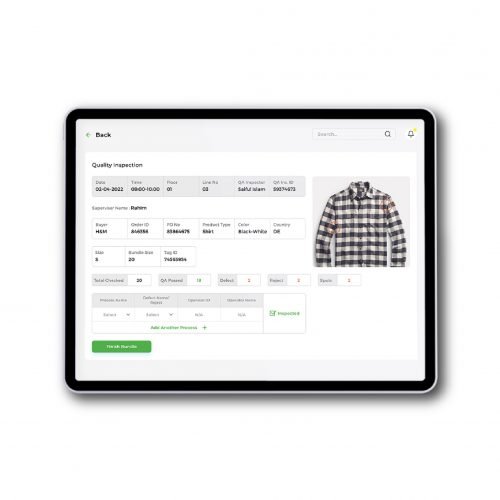

SmartTab

SmartTabs are at the heart of our Quality Management Module. All the Quality data are collected through these tabs and instant KPIs are displayed as well.

SmartCloud Software

Our cloud based software platform provides out-of-the-box tools such as Analytics and visualization with real-time data in a way that is easy to consume and take action from anytime, anywhere.

SYSTEM WORKFLOW

System Workflow

How We Solve Your problem

After the system installation, followings are the main activities to be performed by the factory to make it a successful implementation.

Data preparation

Initially the user needs to enter data into the system like order details, cutting parameters, operation bulletin etc. Data can be imported from excel files or can be added from system menus.

Bundle tag preparation

Bundle tags are prepared by scanning each tag on the RFID tag writer. Depending on the lay plan and marker plan & bundle size details, a bundle list is made on the system. All the RFID tags carry an unique bundle number.

Attaching bundle tag

Attaching bundle tag to each bundle or to individual pieces (in case the factory follows single pieces bundle system). Multiple RFID tags may be required against each bundle depending on the production system in case the garment is processed in different sections at the same time.

Operator terminal setup

Each operator terminal is set-up with a unique terminal id, sewing machine ID and operation ID. Operators login to the terminals by scanning their ID cards when they work on the line. Thus the system acknowledges the operator ID as well.

Scanning bundle tags

When operators work on the bundle they scan the bundle tag (RFID Tag) to the smart terminal. Operators need to scan the bundle tags after completing their process per bundle.

Quality Assurance

When the bundles arrive for the quality inspection, the inspector will punch the bundle card into the smart terminal. The smart terminal will show all the information on the tablet screen assigned for the quality inspector. Then the quality inspector will check all the garments in the bundle one by one & provide the defect, rejection, spot etc information through the tab.

Report reviewing and report inquiry

As soon as operators scan bundle tags after completing their first bundle, LED screens start displaying production details and the display is automatically updated. Line supervisor sees the reports to manage their lines. The operator’s terminal also shows much useful information to the operators.

Reports and data analysis

The system captures all transactions made on the floor, analyzes the data, converts them to KPIs & finally presents informative graphs & reports in real-time to facilitate data-driven problem solving & decision making.

MANAGEMENT MODULES

Merchandising/ Planning

IE and Production

Cutting

Cut Panel Store

Sewing

Quality

KEY DELIVERABLES

Automated Resource Planning

- Manpower requirement forecasting.

- Machine requirement forecasting.

- Raw Material requirement forecasting

- Forecasting the appropriate method.

Production Monitoring & Control

- Ensure smooth materials flow by automatic line balancing.

- Identifications of process bottlenecks.

Capacity Management

- Optimize capacity allocation.

- Balance the workload.

- Benchmark for processes capacity.

Visual Management

- Shop floor visual dashboards.

- Alert about irregularities by traffic light system.

- Visual error detection and prevention strategies.

Skill Management

- Identify current skill deficit and anticipate future skill needs.

- Automatically updated skill matrix from on-job performance.

- Workers’ payroll based on their skill grade.

Live Factory Performance

- Live visibility of factory efficiency with individual accountability.

- Factory performance with financial indicators.

- Live RFT, DHU, and Rejection rate view.

Daily Accountability

- Sewing Operators.

- Supervisor and Incharge.

- Machine Mechanics.

- Management.

Quality Management

- Pen paperless quality data acquisition.

- Live Identification of defects from every workstation.

- Automatic alert through traffic light system & notification.

Changeover Management

- Keep the record of actual changeover time.

- Standardize the change over time for each machine.

- Evaluate changeover efficiency by machine type.

WIP Control

- Live cut panel inventory status.

- Real-time visibility of sewing in-line WIP.

- Set the expected WIP level for each process & control the actual.

- Automatic alert against WIP level by traffic light and notifications.

Downtime Management

- Real-time visibility of sewing process-wise downtime.

- Root causes Identification for downtime.

- Responsible departments Identification for Downtime.

Over-Time Management

- Live OT status of the factory, individual shop floors, lines & processes.

- OT calculations of every worker are automatically counted & recorded.

Forecast the estimation of OT amount for required processes.

Financial Implications

- Real-time visibility of EPM & CM.

- Live status of Loss/Profit from CM.

- Live visibility of financial losses incurred by NPT, inefficiency & poor quality.

- Real-time visibility of daily produced FOB.

Total Productive Maintenance

- Operators can raise any machine problem by a single touch from the terminal.

- Mechanic’s arrival time & maintenance time by problem category is recorded.

- Automatic notification/ alert according to the maintenance schedule.

Automatic Reporting

- Productivity & Efficiency.

- Quality Assurance.

- Downtime & Style Changeover.

- Supply Chain & Inventory.

- Order wise progress tracking.

- Many more…………

Download pdf file

TechRev 4.0 : Smart Factory brochure

THE END RESULTS

DIVE INTO THE FUTURE

The garment industry is undergoing a significant transformation, adapting to ever-evolving market demands while grappling with escalating costs. In this challenging landscape, technology has emerged as the beacon of hope, illuminating the path forward for the garment industry. Its role in reducing costs, enhancing efficiency, and minimizing downtime is pivotal.