EMPOWER YOUR SUCCESS

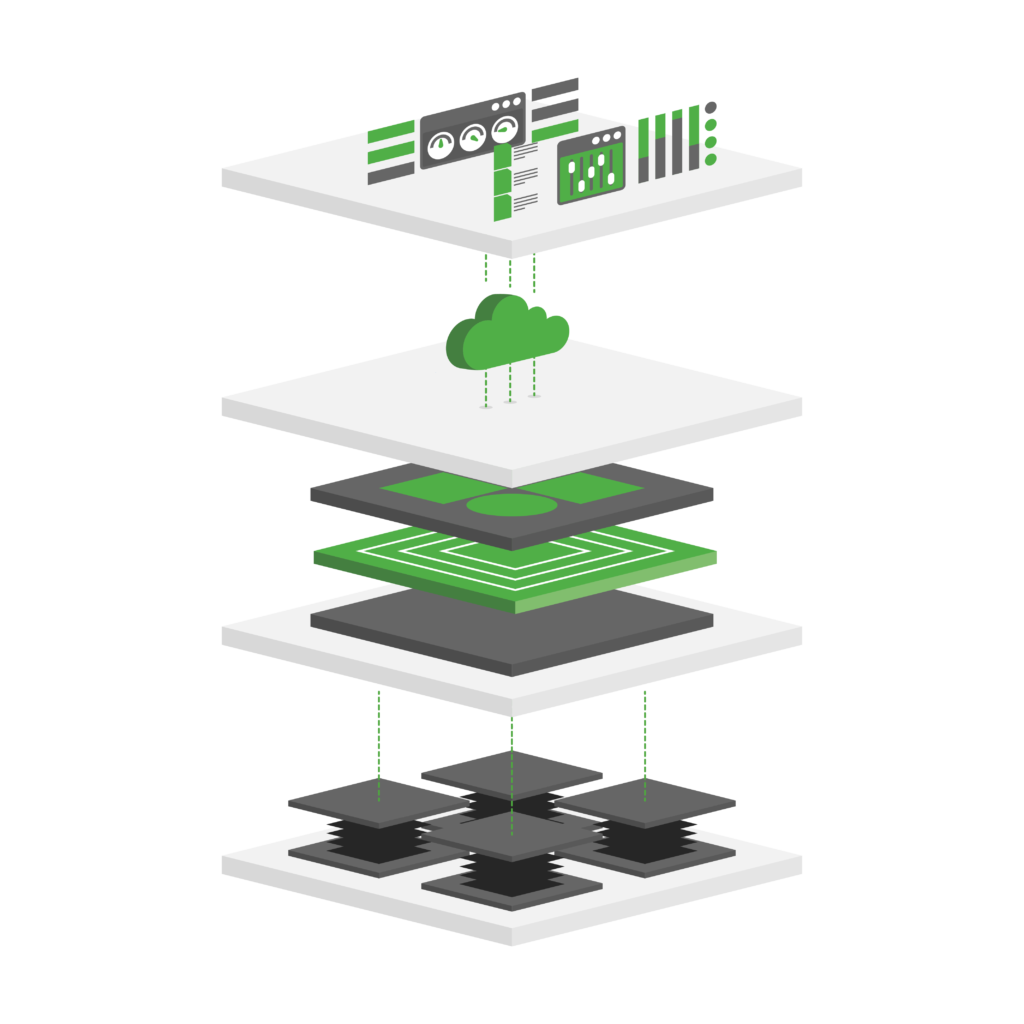

TURNING DATA INTO DECISIONSCONNECT

Connect our smart data terminal device with all kind of digital machines and generate real-time data seamlessly.

GENERATE

Collect and store real-time data in a secured cloud server to access from anywhere, at anytime

VISUALIZE

Convert your data to provide digital visualisation of your entire factory and trend analytics for past operations, enabling precise decision-making, cost reduction, and minimized downtime.

The Hidden Truth

Lack of Real-Time Data

Many manufacturing companies still lack real-time data insights on their shop floors. This gap hinders their ability to make informed decisions, optimize production, and respond swiftly to changing demands. Explore how bridging this data divide can drive efficiency, reduce downtime, and boost competitiveness.

Limited Visibility

Many manufacturing companies face limited visibility across their operations, leading to issues such as production delays, increased costs, and quality control problems. Learn the common challenges stemming from this lack of insight and discover solutions to enhance transparency and efficiency in your manufacturing processes.

MacRev 4.0 : Manufacturing Execution System

CENTRALIZED MONITORING SOLUTION FOR ALL DIGITAL MACHINES

TAKE IMPOSSIBLE DECISIONS

WITH YOUR OWN DATA

MACHINE DATA

Effortlessly establish a seamless connection with your entire fleet and initiate the acquisition of data from your machines.

ERP DATA

Effortlessly integrate your third-party systems to overlay operational context onto your machine data.

HUMAN DATA

Incorporate essential context regarding shop conditions and machine events from employees as required.

MACHINE INSIGHTS

Utilize automated analytics for enhanced insights into your machine's well-being and operational efficiency.

PLANT INSIGHTS

Continuously track and pinpoint production bottlenecks on the shop floor from anywhere, anytime.

BUSINESS INSIGHTS

Assist leaders in understanding how variations in production between different plants impact crucial initiatives.

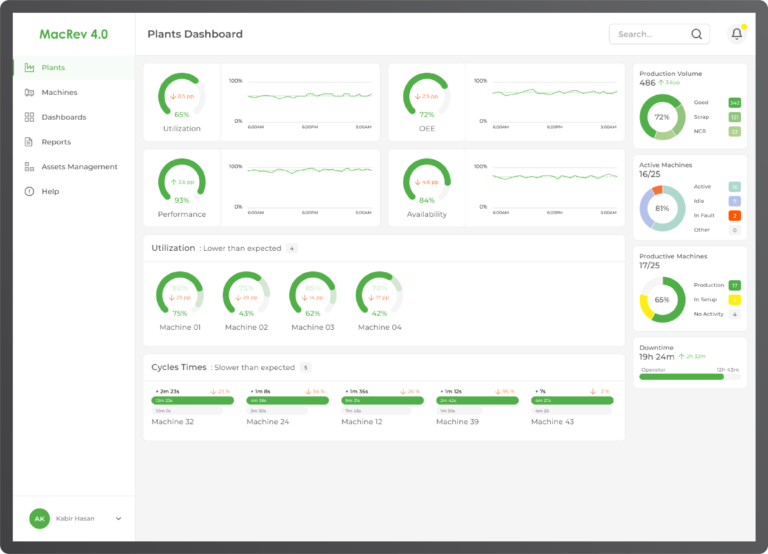

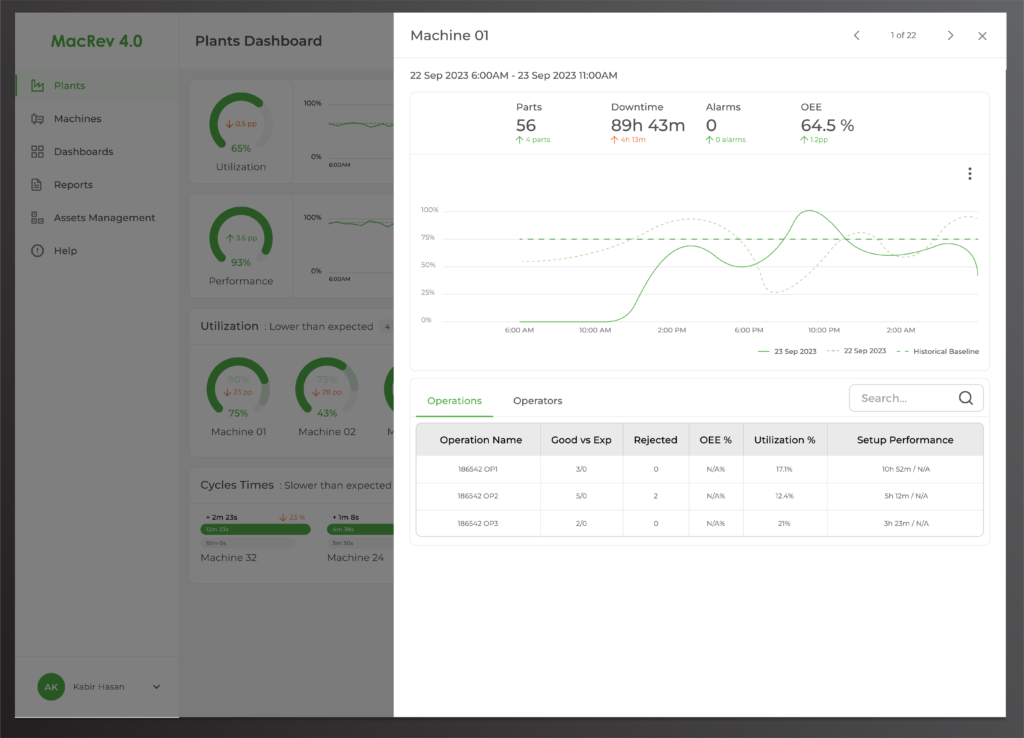

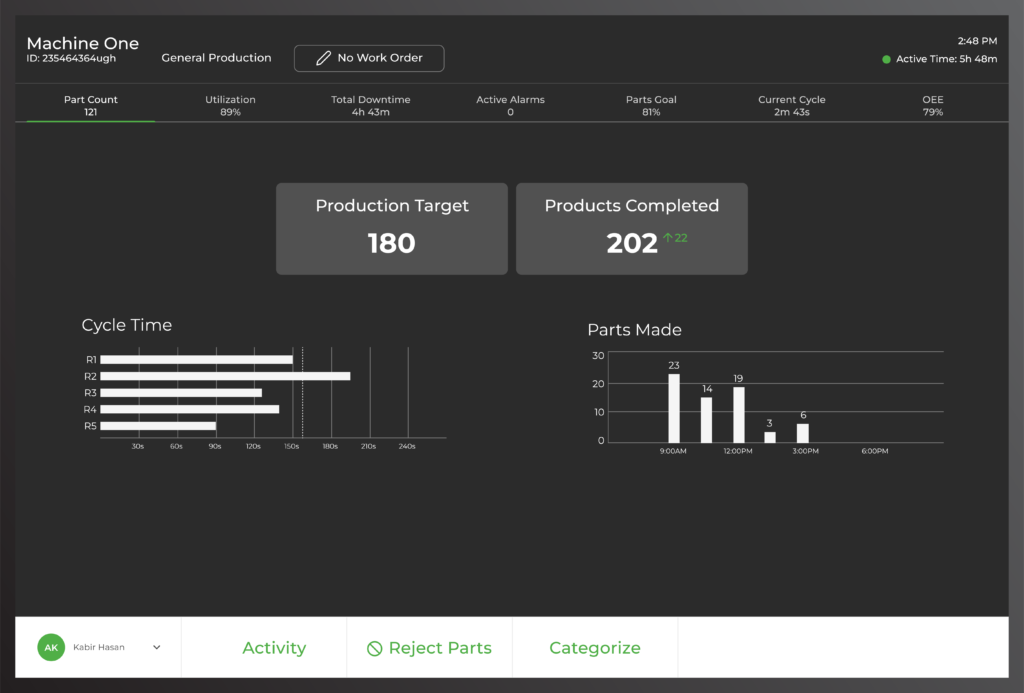

GAIN FULL VISIBILITY OF YOUR PLANT

Your centralized hub for monitoring the performance and enhancement of your machining processes across your entire organization. Evaluate your performance against statistical benchmarks or previous periods.

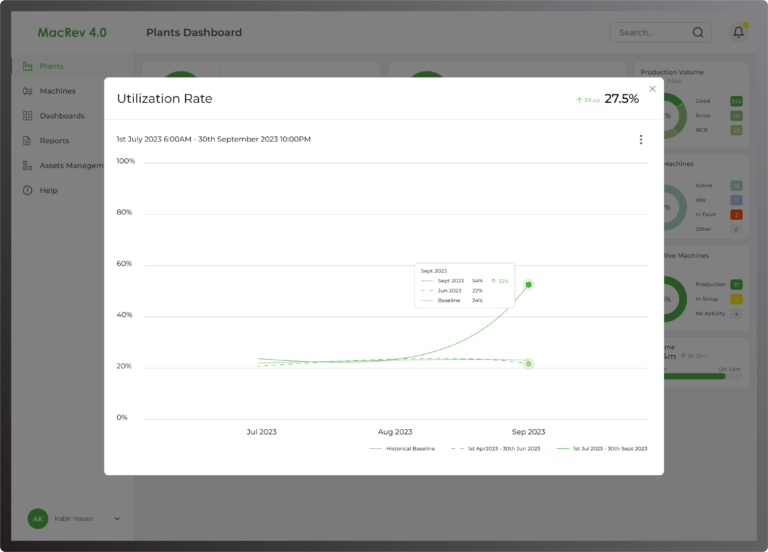

EXAMINE PAST TRENDS

Gain insights into your organization's historical performance by comparing core metrics to corresponding time periods.

ESTABLISH A PRODUCTION BASELINE

Utilizing our latest historical reference points, you can effortlessly assess your machine performance in relation to an automatically generated statistical benchmark.

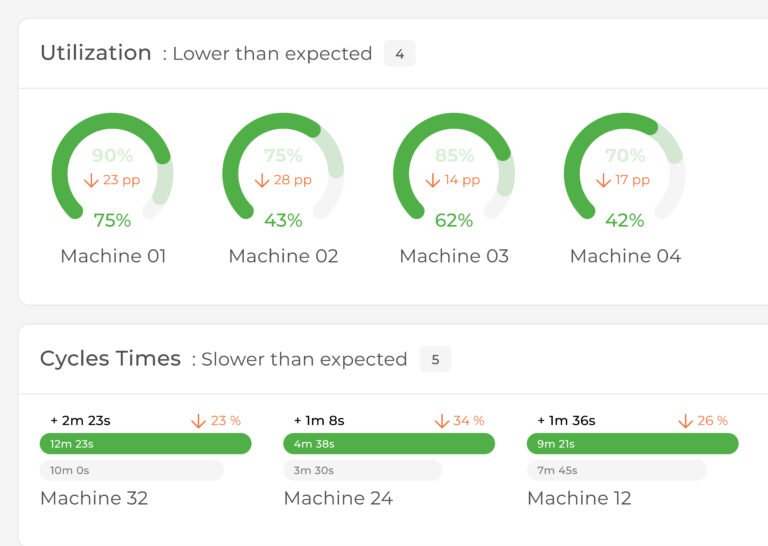

SPEED UP THE ROOT CAUSE ANALYSIS

Swiftly identify machines with underutilization and operations trending below cycle time benchmarks during a recent historical period.

MAGNIFY YOUR PRODUCTION INSIGHTS

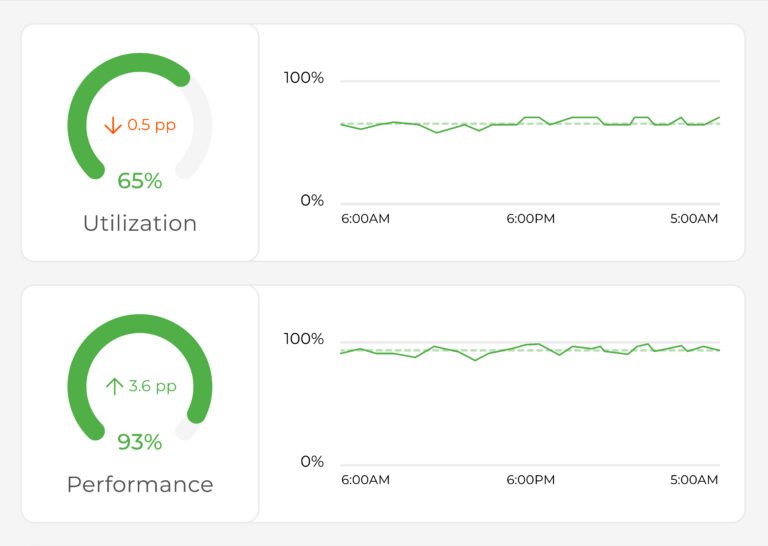

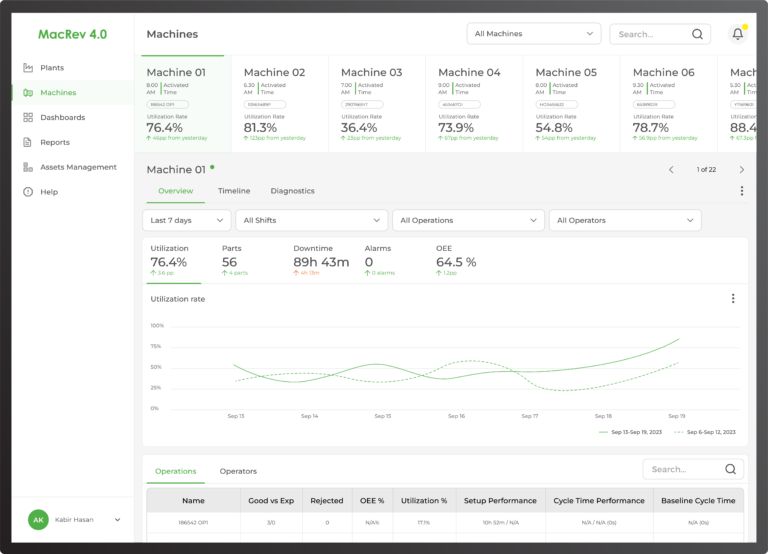

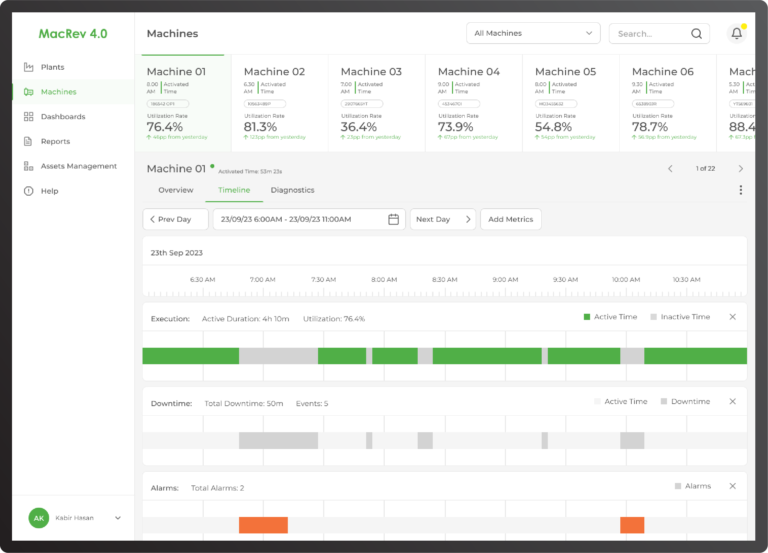

VISUALIZE YOUR OVERALL MACHINES

All-in-one machine data view. Seamlessly switch between key performance metrics, explore trends, and access timelines and diagnostics with a single click.

IDENTIFY MACHINE PROBLEMS

Effortlessly navigate, filter, arrange, and choose from your machines for performance analysis. Swiftly identify underperforming units to enable proactive measures.

EASY INSIGHT NAVIGATION

Eliminate the need for data excavation. We present machine insights to streamline your analysis, saving you hours otherwise spent on combing through multiple reports, ensuring you obtain answers within minutes.

ESTABLISH A PERFORMANCE BASELINE

Utilizing our latest historical references, you can effortlessly assess your machine performance in comparison to an automatically generated statistical benchmark.

FULL IN-DEPTH VISUALIZATION INTO YOUR MACHINES

SIMPLIFIED IN-DEPTH INSIGHTS

Conduct a top-level assessment of your organization's Overall Equipment Effectiveness (OEE) to pinpoint crucial areas requiring enhancement. Dig into availability, performance, and quality metrics to precisely identify the focus areas for resolution.

ESTABLISH A SEAMLESS RELATIONSHIP BETWEEN MACHINES AND OPERATORS

MAXIMIZE MACHINE OPERATOR EFFICIENCY

Replace laborious manual data collection for run time, part counts, and downtimes. Provide proactive notifications that enhance operator efficiency and direct them to the necessary tasks and timing.

Gain valuable insights into the full fleet of your digital machinery, enabling you to meticulously monitor and optimize your manufacturing operations. Take immediate or measurable actions to reduce costs and minimise downtime, which will ultimately boost your production efficiency.

INJECTION MACHINE

EXTRUSION MACHINE

BENDING MACHINE

PUNCHING MACHINE

DRAWING MACHINE

Download pdf file

MacRev 4.0 : Manufacturing Execution System

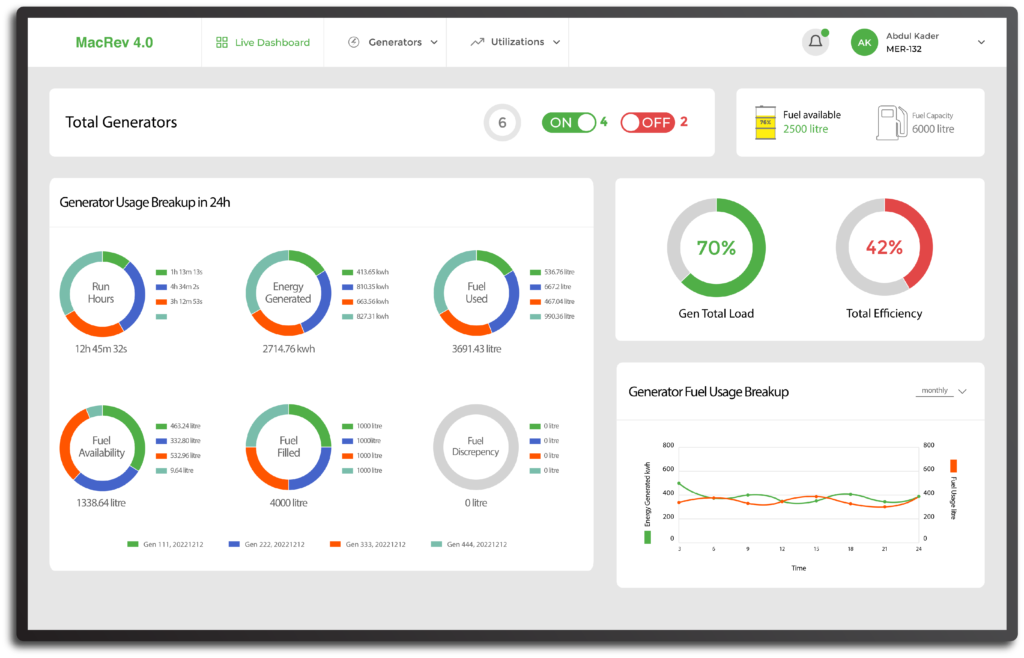

MacRev 4.0 : Energy Management System

MONITORING ENERGY GENERATION & DISTRIBUTION ....anytime, anywhere

KEY FEATURES

Live power generator indicator

Fuel consumption & volume tracking

Unit-wise energy consumption tracking

Run hours monitoring

Battery voltage monitoring

Fuel theft & load imbalance alert

GENERATOR

BOILER

COMPRESSOR

Download pdf file

MacRev 4.0 : Manufacturing Execution System

KEY FEATURES

Applicable for all machines

Our solution is versatile, suitable for both manual and automated sewing machines. It seamlessly integrates with your existing equipment, optimizing productivity regardless of your sewing method.

Monitor needle downtime

Our system excels in data generation, capturing precise metrics for actual stitching time or needle down time. This meticulous data acquisition empowers you with valuable insights into your sewing operations

Monitor RPM

Our advanced system not only monitors RPM with precision but also elegantly pinpoints any instances where a sewing machine is operating below the established benchmark, ensuring the highest levels of operational excellence and efficiency.

Compare stitching & standard time

Conducting a meticulous analysis, our solution facilitates an elegant comparison between the actual stitching time and the predefined, allowable stitching time. This in-depth evaluation ensures that your production process aligns seamlessly with industry standards.

Monitor total work time

Experience the elegance of tracking the percentage of your total working time dedicated to genuine value addition. Our system provides a clear and insightful view, allowing you to understand and optimize the utilization of your resources with precision.

Monitor KPI dashboards

Discover a friendly and precise way to evaluate the working accuracy and precision of your sewing operators on a task-by-task basis. Our solution offers an approachable interface that allows you to assess their performance with ease.

KNITTING

WEAVING

SHOE & BAG

LEATHER